When I was invited to design a towel for the Mayan Hands Dye

Project I joined a team of people who have generously donated time, energy, and technical expertise to help a

group of women committed to learning and perfecting the natural dye

process. Together, for over five years,

they have worked to make the potentially life-changing project a reality.

The publication of Deborah Chandler's article about the project in the most recent issue of Handwoven magazine (Sept/Oct 2014) and my accompanying towel design has sparked the hoped-for response. The first batch of kits sold out quickly, and Cotton Clouds (all proceeds benefit the Guatemalan dyers) has a waiting list for the next batch which is scheduled to arrive soon from Guatemala. Please contact Cotton Clouds to be added to the list.

To say the enthusiastic reception has been affirming and inspiring for the women on the dye team is an understatement. The money they have earned is not just more than what they typically earn; because there is little or no work for them otherwise, the income from the kits is all they are earning.

In an earlier post I wrote that the dye project was done in collaboration with WARP when Mayan Hands is, in fact, an independent member organization of WARP. Founded by Guatemalans Brenda and Fredy Rosenbaum in 1989,

Mayan Hands is a fair trade organization whose mission is to assist women in

their quest to rise from poverty by giving a “hand up,” not a “handout”.

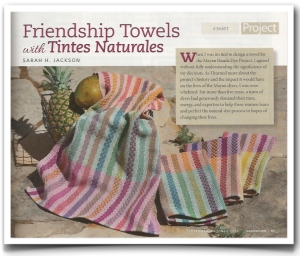

More about the towel design: The huckaback

block design first appeared in Handwoven in 1985 in towels known as

"friendship towels". My design

is a variation of the original, but the name still fits, perfectly appropriate

to describe the affiliation between the weavers who are learning the dye

process and those who appreciate their artistry and reach out in friendship and

support.

It is my hope that the design of the towels honors the efforts of all of those involved in

the Dye Project. I hope, too, that weaving the towels will prompt a deeper

appreciation of the connections and the friendships we forge through our love

of weaving.

One of the team members who deserves special thanks is Rocío Mena Gutierrez.

She provided " information, nudging, inspiration, dedication, fun, and a will to push hard when everyone was tired." (quote, Deborah Chandler). For a fascinating look at Rocio's time in Guatemala with the dyers and their families please read her blog: http://naturaldyeproject.wordpress.com/

She provided " information, nudging, inspiration, dedication, fun, and a will to push hard when everyone was tired." (quote, Deborah Chandler). For a fascinating look at Rocio's time in Guatemala with the dyers and their families please read her blog: http://naturaldyeproject.wordpress.com/